A leading UK manufacturer dedicated to exceptional quality, dependable delivery and industry leading expertise.

A UK Manufacturer of Rubber and Polyurethane Components

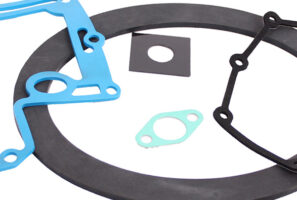

We are Clifton Rubber, an established UK based rubber and polyurethane component manufacturer trading with companies worldwide. Offering the full range of rubber and polyurethane processing capabilities, we make bespoke rubber and polyurethane products to your design and specification as well as producing a range of universal components for specific industry applications.

We are focused on quality and dependability, always striving to manufacture products that exceed your expectations and deliver them to you when required. Plus, with our team of experienced technicians we are sure whatever your rubber or polyurethane product requirements, we will find a successful solution for you.

Our Manufacturing Capabilities

Companies We've Worked With

Case Studies

Industries We Work In

About Us

Since our establishment in 1973, our core business has been the processing of rubber and polyurethane materials to produce customer bespoke products, such as rubber and polyurethane mouldings, rubber and polyurethane covered rollers, rubber extrusions and rubber sheet conversions.

In addition to our bespoke work, we have developed a range of own brand components that can be found in use in various applications around the world, including the agricultural, offshore and transport industries.